WEINIG SOLID JOINT PJ 350 and SOLID JOINT PJ 350-H: Compact lines for specific requirements

The SOLID JOINT PJ 350 series offers several possibilities in terms of execution. You can choose. Depending on what you want to produce, we offer you a system that is adapted to your requirements. The following options are available for the compact line SOLID JOINT PJ 350:

1. SOLID JOINT PJ 350 160 - 2 cycles/min.

The SOLID JOINT PJ 350 160/2 is a continuous compact line that carries out shaping, gluing and “endless” pressing in one process. The maximum lamella width is 300 mm, the maximum cross section is defined by the 16 t thrust force.

2. SOLID JOINT PJ 350 200 - 4 cycles/min.

The SOLID JOINT PJ 350 200 - 4 is a continuous compact line that carries out shaping, gluing and “endless” pressing in one process. The maximum lamella width is 300 mm, the maximum cross section is defined by the 20 t thrust force.

3. SOLID JOINT PJ 350 200/300 - 5.5 cycles/min.

The continuous compact line SOLID JOINT PJ 350 200/300 - 5.5 is available in a 20 t and a 30 t design. The high performance of 5.5 cycles/min is achieved using servo-drives and proportional hydraulics. Any end length can be provided using electronic length measurement and cutting is done using the integrated saw.

4. SOLID JOINT PJ 350 – H (horizontal)

The SOLID JOINT PJ 350-H is a compact line that can be used to produce a horizontal finger joint, for example for timber house planks. Just as in the other compact lines, the shaping, gluing and pressing take place in one clamping process.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

WEINIG compact lines offer you

- Very compact construction of different lines

- Pressing force of 20, 30 or even 40 tonnes

- Capacities of 3.5 up to 15 joints/min possible

- Optionally available with additional sound insulation cabinet

- Production of an endless phase

- With splinter protection to avoid splintering in the timber

- Glue comb systems or contact-free glue application

WEINIG SOLID JOINT PJ 350 series offers you

- Shaping, gluing and pressing in one clamping process (up to 5.5 cycles/min)

- Large timber dimensions up to 310 mm timber width possible

- Almost all types of glue can be used

- Splinter protection as standard, every line

- Modular system - adapts to your requirements

- High pressing forces up to 400 kN (40 t)

- Production of an endless phase

- For CLT, glued laminated timber, KVH or also glued window scantlings

- Infeed length up to 6,000 mm

- A compact line for horizontal joints is also available

Technical Details

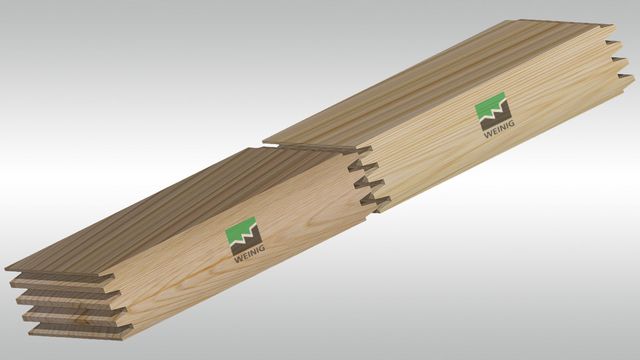

Vertical finger joint

The vertical profile is mainly applied in constructive woodworking, but is also used for building windows and frames. It is has the largest glue surface and is therefore the most stable of all finger joints.

Horizontal finger joint (only in SOLID JOINT PJ 350-H)

References